How It Works

The LINX 600 System

The LINX 600 System is our first Industrial product. It can treat up to 170 tons of feed water per day. For larger volumes, multiple LINX 600 systems are configured in parallel and series. This product is comprised of six LINX cells, four operating in deionization (a coarse cell pair and a polish cell pair), and the third cell pair in regeneration. Cell pairs change roles after a short pre-determined time to provide continuous water treatment at up to 120 L/minute.

The LINX 600 system is fully automated – it will shut itself off if conditions warrant it and deliver warnings when conditions may be approaching a problem level. Furthermore, a one hour cleaning process using strong mineral acid is initiated either automatically, or manually as scheduled, to return LINX cells to their original performance if scale or COD has accumulated. The LINX 600 system can also be operated intermittently to fill a large tank, such as to provide safe drinking water for small communities. Our next generation product, now in development, is the LINX 1000 platform – a custom designed system comprised of up to 150 LINX cells for very large production volumes.

HOW LINX TECHNOLOGY WORKS

ERIX Solutions invented our Electrically Regenerated Ion Exchange technology (our tradename is LINX® technology) to create the first commercial devices that provide water purification chemical free, using electricity rather than chemicals to practice the ion exchange process.

Figure 1 illustrates a cross-sectional view of a simple LINX cell. Feed water enters the inlet at the top of the figure, flows between the water-splitting membranes, and exits via the outlet at the bottom of the figure. There is one contiguous water channel in the cell, rather than the two present in electrodialysis cells.

As seen in Figure 1, water-splitting membranes are comprised of two layers: a cation exchange material (e.g. P-SO3H or P-COOH) which is secured to an anion exchange material (e.g. P-NR3OH or P-NR2). Water-splitting membranes and apparatus were well known before the invention of LINX systems, and are used for the production of acid and base chemicals from simple salts in electrodialysis cells. ERIX Solutions has invented and manufactures for captive use water-splitting membranes optimized for use in LINX devices.

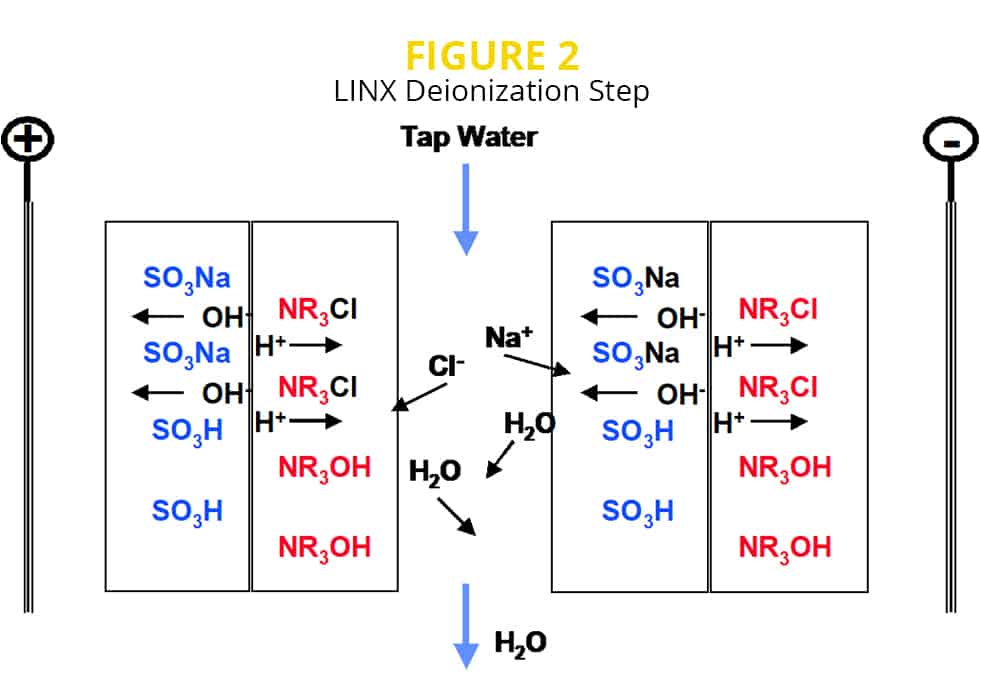

As an example, the deionization step for removing sodium chloride from solution is shown in Figure 2. This is the classic ion exchange process in which the cation and anion exchange materials are in the acid (H+) and base (OH–) forms, respectively, at the outset of deionization.

In the LINX chemical free water treatment process, however, a voltage is applied during the deionization step to accelerate ion extraction (ions move faster in the electric field). The negatively charged chloride (Cl–) ions migrate toward the anode (positive electrode) to replace OH- ions, and the positively charged sodium (Na+) ions migrate toward the cathode (negative electrode) to replace the H+ ions. OH– and H+ combine to form water, H2O, so the net result is the deionization of water.

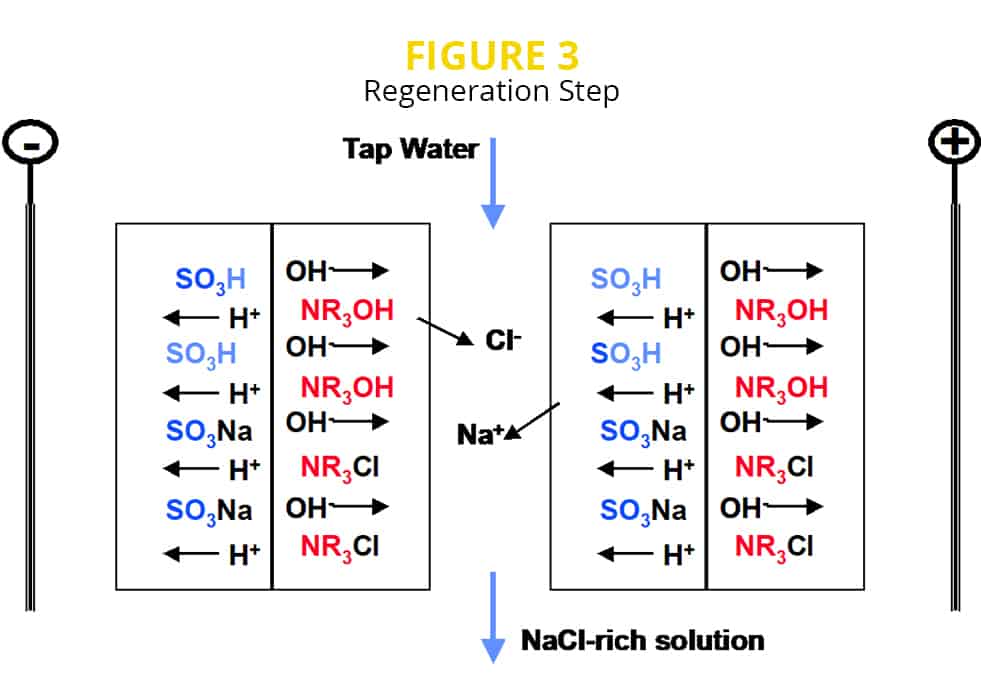

When the absorbtion capacity for sodium and chloride ions of the two ion exchange materials is significantly reduced, the regeneration process in Figure 3 is initiated. The polarity of the two electrodes is reversed so that the water-splitting reaction at the boundary between the anion and cation exchange layers produces acid (H+) and base (OH–) which migrate through the cation and anion exchange materials, respectively. They reject the absorbed sodium and chloride ions into a concentrate between membrane layers and return the cation and anion layers to the acid (H+) and base (OH–) forms. When regeneration is complete, another deionization step is initiated.

Unique LINX Water System Advantages*

- Reduction of N, P, heavy metals, COD

- Enable waste water reuse, zero emissions

- 10-fold concentration of waste

- Resistant to fouling by oils, COD, particles

- Compact equipment for Municipal facility nitrate reduction

- Selective removal of nitrates, metals, COD

- Electrical operation – chemical free water purification

- Best (90%) water recovery

- Good cold weather performance

- Original performance after strong acid clean

- One-step, low cost salt removal from slurries

- Eliminate the slow diafiltration process

- Self-disinfecting (log 6 bacterial reduction)

- Clean-in-place (CIP) with strong acid

- Electrical operation

* Compared to reverse osmosis (RO)

and ion exchange (IX) – See Appendix